Nitrogen Generator consists of two tanks containing CMS (Carbon Molecular Sieve). The air pressurized by passing through the air conditioning equipment enters the nitrogen generator from the bottom of the first tank, passes through all the CMS in the tank and sends it in pure form to the nitrogen stock tank through the generator. Meanwhile, oxygen, argon, carbon monoxide and other gases retained by the CMS are released to the atmosphere through exhaust. After the first tank is finished at the time interval set by the touch control panel, conditioned air enters from the bottom of the second tank and passes through the entire CMS and is sent in pure form through the generator to the nitrogen stock tank. Thus, uninterrupted nitrogen gas production is ensured by the tandem (synchronous) operation of two tanks filled with CMS.

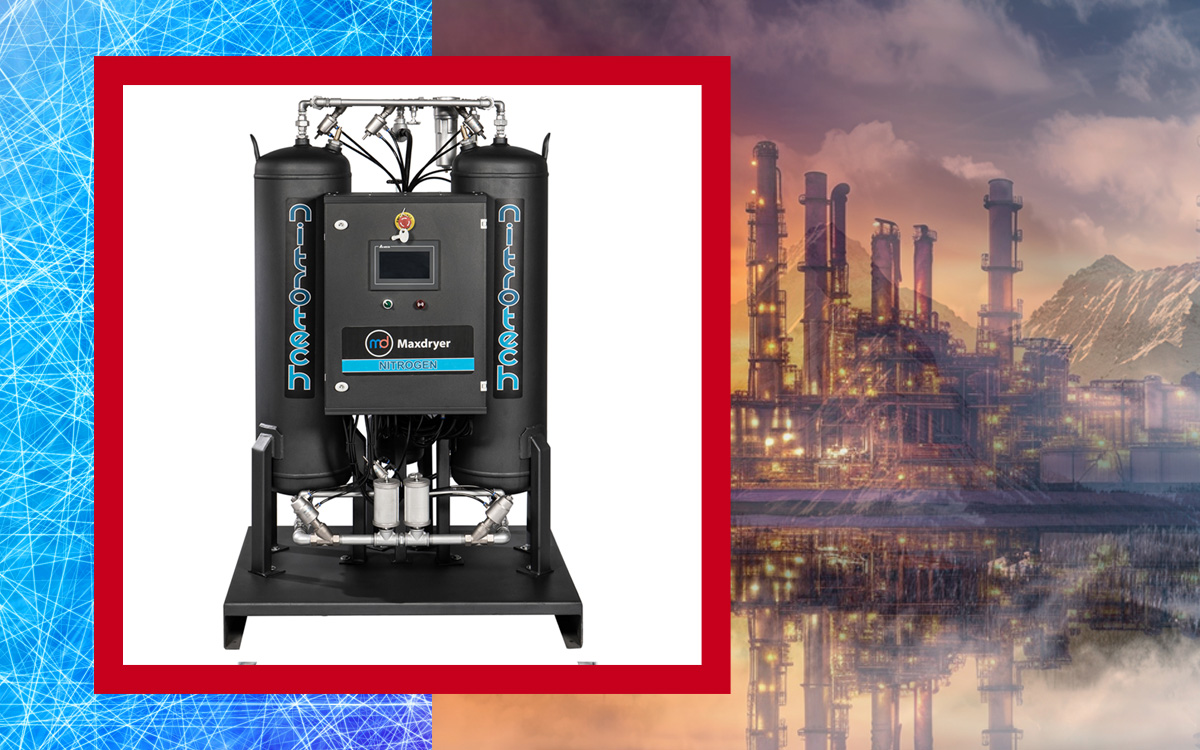

Working Principle of Nitrogen Generator

Nitrogen generators basically consist of two CMS-containing tanks. These tanks are chambers through which pressurized air is sequentially passed and the nitrogen gas is purified. The principle of operation can be summarized as follows:

- Air Preparedness: The ambient air is cleaned, dried and brought to a certain pressure with the help of air conditioning equipment.

- Adsorption: The prepared air enters through the bottom of the first tank and passes through the CMS bed. The CMS has the ability to separate gases according to their molecular size. Gases with smaller molecules such as oxygen, argon, carbon monoxide are retained by the CMS, while nitrogen molecules are larger and pass through the CMS and exit through the top of the tank.

- Desorption After a certain time, the CMS bed in the first tank becomes saturated with oxygen and other gases. In this case, the air flow is diverted to the second tank and the same process is repeated. The CMS bed in the first tank is taken into the regeneration process by depressurizing and purging with pure nitrogen gas.

- Nitrogen Production: In this way, a continuous production of nitrogen gas is ensured by the sequential operation of the two tanks. The pure nitrogen gas produced is sent to the nitrogen storage tank and distributed to the points where it is needed.

- What is a CMS? CMS is a carbon-based material with a porous structure that has the ability to selectively retain molecules of certain sizes. Used in nitrogen generators, CMS allows the passage of nitrogen molecules while retaining other gas molecules such as oxygen, argon, carbon monoxide.

- CMS (Carbon Molecular Sieve): A high purity carbon-based adsorbent used to separate nitrogen gas from other gases.

- Air Compressor: Equipment that brings the ambient air to the required pressure.

- Air Dryer: Equipment that removes moisture from the air.

- Air Filters: Equipment that traps dust and particles in the air.

- Control Panel: It is the panel that controls the operation of the generator and makes the necessary settings.

Nitrogen Generator