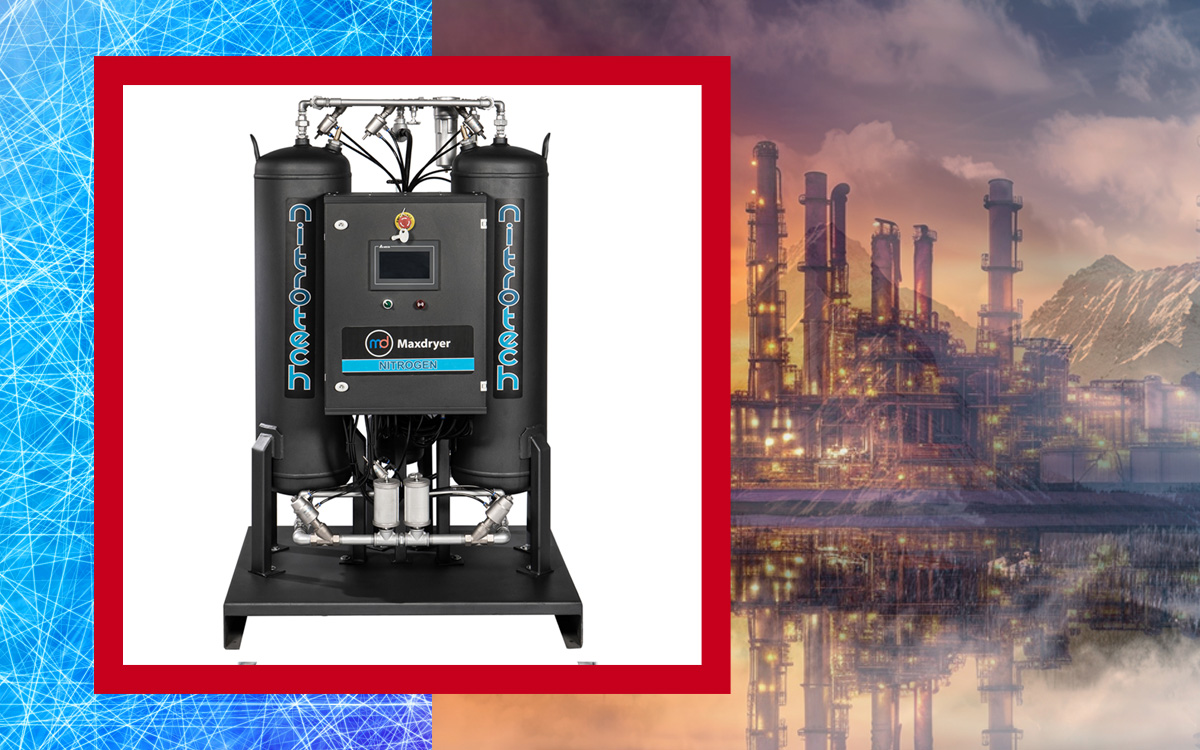

Nitrogen Generator

Today, many industries require high purity nitrogen gas. Nitrogen is a critical component in many fields such as metal processing, food packaging, chemical industry and laboratory applications. To meet these needs, a nitrogen generator offers an important solution in terms of both cost effectiveness and efficiency.

What is a Nitrogen Generator?

Nitrogen generators are systems capable of producing nitrogen gas from air taken from the atmosphere. Usually using PSA (Pressure Swing Adsorption) or membrane technology, nitrogen and oxygen in the air are separated to produce high purity nitrogen gas. These systems can be customized according to the amount of nitrogen needed.

Advantages of Nitrogen Generators

- Cost Savings: Nitrogen generators offer a cost-effective solution for businesses that require large volumes of nitrogen gas. Producing your own nitrogen instead of outsourcing gas provides significant savings in the long run.

- Uninterrupted Gas Supply: Since generators can continuously produce nitrogen, they prevent interruptions in gas supply to businesses.

- Customizability: Customizable systems can meet different demands in various industries.

- Environmentally Friendly: These air-powered systems offer an environmentally friendly alternative as they do not require chemical treatments.

Application Areas

- Food and Beverage: Nitrogen gas is used to extend the shelf life of food products and prevent oxidation.

- Metal Processing: Plays a critical role in protecting metal surfaces and preventing oxidation.

- Chemical Industry: Used in the preservation of reaction media and as an important component in various chemical processes.

- Laboratories: High purity nitrogen gas is required for precision experiments.

- Energy Sector: Various applications in the oil and gas industry.

- Laser cutting is a manufacturing method in which materials are cut using a high-energy laser beam. In this process, the quality and speed of the cut are directly dependent on the type and purity of the gas used. Nitrogen gas is one of the most commonly used gases in laser cutting and offers many advantages.

Why is a Nitrogen Generator Important?

- High Purity Nitrogen: Nitrogen generators are capable of producing nitrogen gas at the purity required by your application.

- Continuous and Reliable Supply: By producing your own nitrogen, you eliminate dependence on external gas supplies.

- Cost Savings: In the long run you save on nitrogen cylinder purchasing and transportation costs.

- Environmentally Friendly: Nitrogen generators are an environmentally friendly and sustainable solution.

- Safe to Use: Modern nitrogen generators are safe and easy to use.

What to Consider When Choosing a Nitrogen Generator?

- Nitrogen Purity: The level of nitrogen purity required by your application.

- Nitrogen Flow: The amount of nitrogen you need.

- Operating Pressure: The operating pressure in your system.

- Energy Consumption: Jeneratörün enerji verimliliği.

- Maintenance Requirements: Ease of maintenance of the generator.

How Does a Nitrogen Generator Work?

Nitrogen generators are devices used to separate and purify nitrogen from the air around us. They basically work with two main technologies:

- PSA (Pressure Swing Adsorption): In this method, compressed air is sent into a container containing a special adsorbent (usually carbon molecular sieve). Other gases, such as oxygen, adhere to this adsorbent, while nitrogen molecules are smaller and pass through, resulting in purified nitrogen. The process is repeated, reducing the pressure and cleaning the adsorbent.

- Membrane Technology: In this method, compressed air is passed through a special polymer membrane. As oxygen and other small molecules pass through the pores of the membrane, larger nitrogen molecules are trapped and pure nitrogen is obtained.

Different Nitrogen Generator Types

- PSA Nitrogen Generators: Ideal for higher purity nitrogen production. Can be used in a wide flow range.

- Membrane Nitrogen Generators: Suitable for lower purity nitrogen production. It is more economical thanks to its simple structure.

- Combined Systems: Systems that use both PSA and membrane technologies together. It can be customized according to different needs.

Maintenance and Repair of Nitrogen Generator

Regular maintenance is important to extend the life and increase the efficiency of nitrogen generators. Maintenance operations usually include:

- Changing filters: Regular cleaning or replacement of the filters in the air intake extends the life of the system.

- Refreshing the adsorbent (PSA systems): Adsorbent performance can degrade over time, so it needs to be refreshed periodically.

- Seal tightness check: Leaks in the system reduce efficiency and cause energy loss.

- Electrical check: Regular checks of electrical components prevent malfunctions.

Frequently Asked Questions About Nitrogen Generators

- How much energy do nitrogen generators consume? Energy consumption varies according to the capacity of the generator, operating conditions and the technology used.

- What is the lifetime of nitrogen generators? With regular maintenance, nitrogen generators can operate for many years without any problems.

- In which sectors are nitrogen generators used? Nitrogen generators are used in food, electronics, metallurgy, chemistry, pharmaceuticals and many other sectors.

- What should I consider when buying a nitrogen generator? You need to consider factors such as the nitrogen flow rate, purity level and working pressure you need. The manufacturer's experience and service network are also important.

- Are nitrogen generators safe? Yes, nitrogen generators are safe when used correctly. However, it is important to pay attention to safety precautions.

How to Learn Maximum Machine Nitrogen Generator Prices?

You can follow the steps below to get detailed information about Maksimum Makina nitrogen generator prices:

- Apply to Maksimimum Makina Communication Channels: You can specify your needs and budget by contacting the company's website, phone or e-mail.

- Get a Quote: Once a nitrogen generator model suitable for your needs has been selected, you will be offered a special price quote.

- Compare: You can choose the most suitable option by comparing the offers of different companies.

Factors Affecting Maximum Machine Nitrogen Generator Prices

Nitrogen generator prices vary depending on many factors. Among these factors are the following:

- Capacity: Hourly nitrogen production capacity is one of the most important determinants of price. High capacity generators are generally more expensive.

- Purity: The purity level of the nitrogen gas produced also affects the price. For applications requiring high purity nitrogen, more advanced and therefore more expensive generators are preferred.

- Additional Features: Additional features in generators (e.g. dehumidification system, pressure control) can increase the price.

- Brand and Model: Different models of brands such as Maksimum Makina may have different prices.

- Market Conditions: Factors such as exchange rates, raw material prices and general economic conditions can also affect prices.

Why Investing in a Nitrogen Generator is Profitable?

Investing in a Nitrogen generator offers many advantages in the long run:

- Cost Savings: Producing your own nitrogen instead of buying bottled nitrogen provides significant cost savings in the long run.

- Continuous Nitrogen Supply: With your own generator, you have access to the desired amount of nitrogen gas at any time.

- Environmentally Friendly: Nitrogen generators are an environmentally friendly solution. Bottled nitrogen eliminates the environmental impacts associated with transportation and storage.

- Reliability: Since you have your own production facility, you are no longer dependent on external sources of supply.

Produce Nitrogen Gas Sustainably with Nitrogen Generator!

Nitrogen generator plays an important role in meeting industrial needs. It has become an indispensable part of businesses with its cost-effectiveness, continuous gas supply and environmentally friendly features. It will be the right investment to evaluate the nitrogen generator to meet the nitrogen needs of your business and increase your productivity.

Key words: nitrogen generator, nitrogen gas, nitrogen generators, nitrogen generator, nitrogen gas, industrial gas, laser cutting nitrogen gas, laser cutting nitrogen generator, food industry, electronic industry, chemical industry, metal processing, power sector, high purity nitrogen, continuous nitrogen supply, cost saving, environmentally friendly, safe use.

Contact us immediately for your nitrogen generator needs.