Capacity, Purity and Cost Factors to Consider

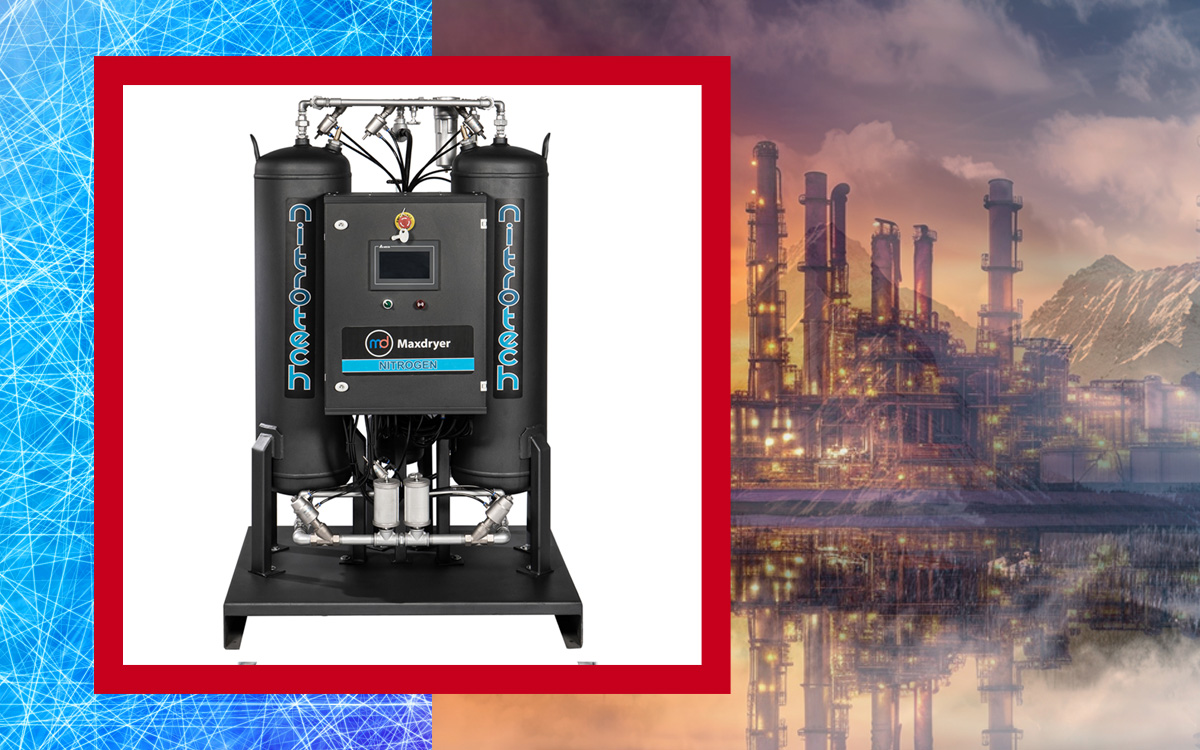

Nitrogen generatoris an important solution for on-site production of nitrogen gas used in many industries. For businesses, choosing the right nitrogen generator is critical for efficiency, cost savings and operational continuity. In this article, we will discuss how businesses should choose the right nitrogen generator for their needs, addressing factors such as capacity, purity and cost.

Choosing the right nitrogen generator for businesses requires a careful evaluation process. Capacity, purity, cost, generator type and other factors should be taken into account to determine the most suitable generator for the needs of the business. In this way, businesses can meet their nitrogen gas needs, save costs and increase their operational efficiency.

Solutions Tailored to Your Needs

Nitrogen generators are critical equipment used to produce high purity nitrogen gas in industrial processes, laboratories and many other industries. Choosing the right nitrogen generator can help you reduce costs while increasing the efficiency of your business. So how do you choose the best nitrogen generator for your needs? Here are the factors you need to consider:

- Determine Your Nitrogen Needs

The first step in choosing the right nitrogen generator is to clearly identify the nitrogen needs of your business. You can start by looking for answers to the following questions:

- What is your daily nitrogen consumption?

- What is the purity of the nitrogen needed?

- How often do you use nitrogen gas?

These questions will help you determine the capacity and technology of the generator.

- Pay Attention to Nitrogen Purity Ratio

Nitrogen generators can produce nitrogen with different purity ratios. For example:

- 95-99.5% purity: Suitable for applications such as food packaging, fire extinguishing systems.

- 99.9999% purity and above: It is used in areas requiring high purity, such as laboratories, electronics manufacturing, laser cutting and the pharmaceutical industry.

By determining the purity rate you need, you can avoid unnecessary costs.

- Choose Generator Technology

Nitrogen generators have basically two different technologies:

- PSA (Pressure Swing Adsorption) Nitrogen Generators: It produces nitrogen by separating oxygen and other gases in the air by adsorption. Ideal for medium and high purity nitrogen needs.

- Membrane Nitrogen Generators: It uses membrane technology to separate gases. Suitable for low and medium purity nitrogen production.

You can determine which technology is right for you based on your needs and budget.

- Evaluate Energy Efficiency

Nitrogen generatorcan be a significant cost item in terms of energy consumption, especially in continuous use. Models with high energy efficiency will help you reduce your operating costs in the long run. For this reason, be sure to examine the energy consumption values of the generator.

- Ease of Installation and Maintenance

The installation and maintenance of a nitrogen generator is critical to the continuity of your business. Choosing models that are easy to install, have low maintenance requirements and easy to obtain spare parts will help you avoid possible problems.

- Budget and Turnaround Time

When purchasing a nitrogen generator, you should focus not only on the initial cost, but also on the long-term returns. While a high-quality generator may require a higher initial cost, it can pay for itself in a short time thanks to low operating costs and long life.

- Reliable Supplier Selection

When choosing the right nitrogen generator, it is essential to work with a reliable supplier. By choosing companies that stand out with their experience in the sector, customer references and technical support, you can get a reliable partner in the post-purchase process.

Choosing the right nitrogen generator provides a solution that suits your business needs, while helping you reduce your costs in the long term. You can choose the generator with the most appropriate technology by considering your nitrogen needs, purity rate and budget. Remember, choosing the right equipment directly affects the efficiency and profitability of your business.

Key words: nitrogen generator, nitrogen gas, nitrogen generators, nitrogen generator, nitrogen gas, industrial gas, laser cutting nitrogen gas, laser cutting nitrogen generator, food industry, electronic industry, chemical industry, metal processing, power sector, high purity nitrogen, continuous nitrogen supply, cost saving, environmentally friendly, safe use.

Contact us to learn all the details you should pay attention to when purchasing a nitrogen generator and get expert support!