Nitrogen gas is an important gas used in many industries. In industries such as food, chemicals, metals, laser cutting and electronics, nitrogen gas is used for different purposes. There are two different methods to meet the need for nitrogen gas: Nitrogen generator and nitrogen cylinder.

What is a Nitrogen Generator?

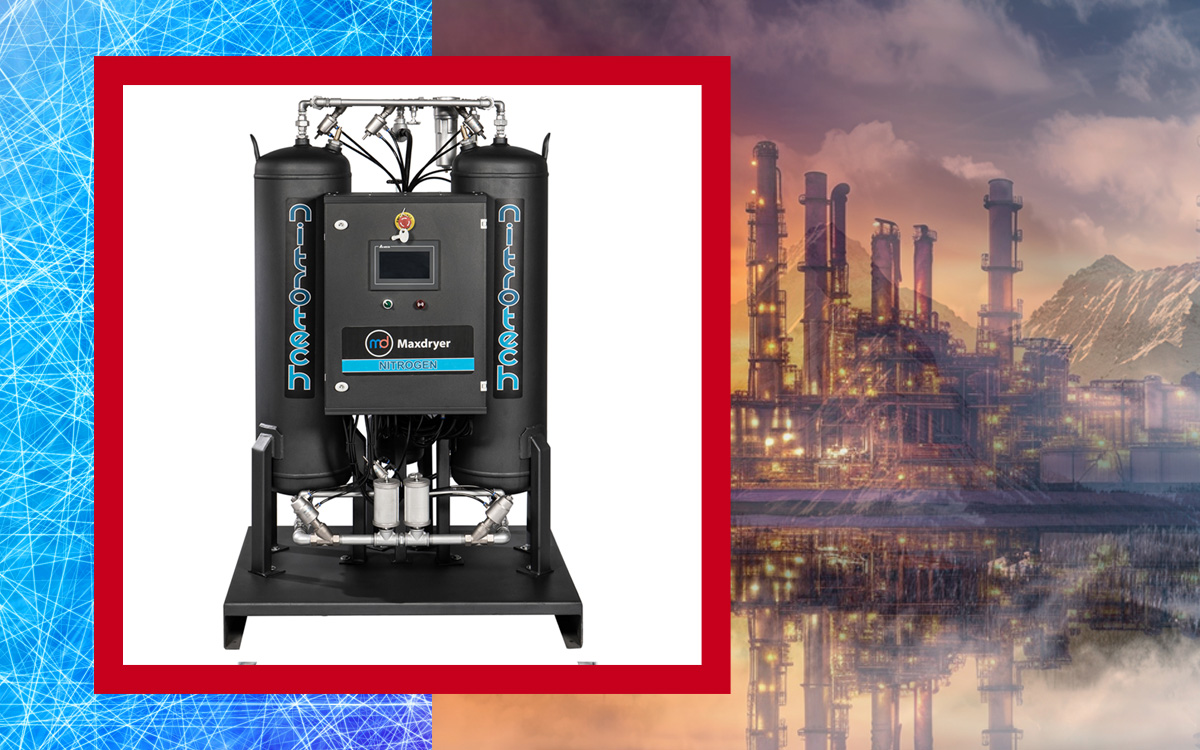

Nitrogen generators produce nitrogen gas using air from an air compressor. In this method, the air from the air compressor is directed into columns filled with a special adsorbent material. The adsorbent material allows nitrogen gas to pass through while retaining oxygen. Thus, high purity nitrogen gas is obtained.

What is a Nitrogen Cylinder?

Nitrogen cylinders are vessels containing nitrogen gas compressed under high pressure. Nitrogen cylinders are often used in small-scale applications.

Advantages of Nitrogen Generator:

- Continuous Production:

- Nitrogen generators can produce nitrogen gas continuously according to demand. It does not require cylinder reinforcement.

- Low Cost (Long Term):

- Although the initial investment cost is high, it saves on cylinder filling and logistics costs in the long run.

- Easy to Use:

- Once installed, it works continuously with minimal maintenance. It can be automatically adjusted to the required purity and flow rate.

- Environmentally Friendly:

- Reduces the carbon footprint of cylinder transportation and filling.

- Flexibility:

- It can be adjusted to suit various purity and flow rate requirements.

Disadvantages of Nitrogen Tobacco:

- Continuity Problem:

- When the cylinders run out, new ones have to be procured, which can cause work interruptions.

- High Logistics Cost:

- Filling, transporting and storing tubes can be time-consuming and costly.

- Storage Space Requirement:

- Especially if large quantities of nitrogen are used, a large storage space for the cylinders is required.

- More Costly in the Long Term:

- Continuous cylinder filling and logistics costs increase total cost in the long run

Nitrogen Generator and Nitrogen Cylinder Comparison

There are many differences between a nitrogen generator and a nitrogen cylinder. Here are some of these differences:

- Cost: Nitrogen generators are more economical than nitrogen cylinders in the long run. However, the initial investment cost is higher in nitrogen generators.

- Amount of nitrogen supplied: While nitrogen generators produce nitrogen gas continuously, nitrogen cylinders provide a limited amount of nitrogen gas.

- Nitrogen purity: Nitrogen generators produce high purity nitrogen gas, while nitrogen cylinders provide lower purity nitrogen gas.

In Which Situations Should Nitrogen Generators and Nitrogen Cylinders Be Used?

When choosing a nitrogen generator and nitrogen cylinder, factors such as the intended use, the amount of nitrogen needed and the budget should be taken into consideration.

- Nitrogen cylinders: They are preferred in small-scale applications where there is no constant need for nitrogen gas.

- Nitrogen generators: In large-scale applications, where there is a constant need for nitrogen gas, nitrogen generator is preferred.

Which one should be preferred in which situation?

- Nitrogen Generator:

- If you need continuous and high amounts of nitrogen,

- If you want to check the purity level,

- If you don't want to deal with logistics and cylinder filling.

- Nitrogen Cylinder:

- If you have low or occasional nitrogen needs,

- If mobile and on-site nitrogen use is required,

- If your initial investment budget is limited.

Nitrogen generator and nitrogen cylinder are both methods used to meet the need for nitrogen gas. However, each method has its own advantages and disadvantages. When choosing a nitrogen generator and nitrogen cylinder, factors such as the intended use, the amount of nitrogen needed and the budget should be considered.

Note: This article provides general information about Max Dryer PSA nitrogen generators. For more detailed information, you can contact Max Dryer officials.

Keywords: nitrogen generator, nitrogen gas, nitrogen generators, nitrogen generator, nitrogen gas, industrial gas, laser cutting nitrogen gas, laser cutting nitrogen generator, food industry, electronics industry, chemical industry, metal processing, energy sector, high purity nitrogen, continuous nitrogen supply, cost savings, PSA nitrogen generator, Max Dryer, nitrogen production, industrial gas, carbon molecular sieve, inert atmosphere, food industry, pharmaceutical industry, metal processing, electronics industry, Map Food Gas, Nitrogen generator, Nitrogen generators, environmentally friendly, safe use.

Contact us immediately for your nitrogen generator needs.