Versatile Uses of the Nitrogen Generator

From Laser Cutting to the Food Industry: Versatile Uses of Nitrogen Generators

Nitrogen is an inert gas frequently used in industrial processes. Thanks to its ability to react with oxygen, it undertakes important tasks such as preventing oxidation, preventing combustion and increasing product quality in many areas. Nitrogen generator provides significant advantages to businesses by producing this valuable gas on-site. In this article, we will examine in detail the areas of use of nitrogen generators in different sectors.

Areas of Use of Nitrogen Generator

Nitrogen generators have a wide range of uses. Here are some important examples:

- Metalworking:

- Laser Cutting: In laser cutting processes, nitrogen generator provides cleaner and faster cutting by removing oxygen from the cutting area. At the same time, it prevents deformation of materials by reducing the heat generated during cutting.

- Welding: In welding processes, the nitrogen generator prevents oxidation and porosity formation by covering the weld pool with an inert atmosphere.

- Heat Treatment: In heat treatment processes, nitrogen generator improves the surface quality of the products and prevents oxidation.

- Electronics:

- Electronic component production: In sensitive processes such as semiconductor production, PCB production, nitrogen prevents static electricity and prolongs the life of products by preventing oxidation.

- Food:

- Packaging: During the packaging of food products, nitrogen generator removes oxygen, prevents products from spoiling and extends their shelf life.

- Wine production: In wine production, nitrogen generator prevents the oxidation of the wine and preserves its aroma and flavor.

- Chemistry:

- Chemical reactions: In chemical reactions, nitrogen generator reduces the risk of combustion by providing an inert atmosphere and preserves the purity of the products.

- Energy:

- Oil and gas: In the oil and gas industry, nitrogen generators are used for cleaning pipelines, inerting tanks and reducing the risk of fire.

- Medicine:

- Medical device production: During the production of medical devices, the nitrogen generator extends the life of the devices by preventing oxidation.

Advantages of Nitrogen Generator

- High purity nitrogen: Production of nitrogen with the desired purity for different applications.

- Continuous and uninterrupted nitrogen supply: No external nitrogen supply is required.

- Maliyet etkinliği: Uzun vadede azot satın alma maliyetlerinden tasarruf sağlar.

- Environmentally friendly: Energy efficiency and low emission levels.

- Safe to use: A safe system with low risk of explosion.

Produce Nitrogen Gas Yourself with Nitrogen Generator, Save Money in Production!

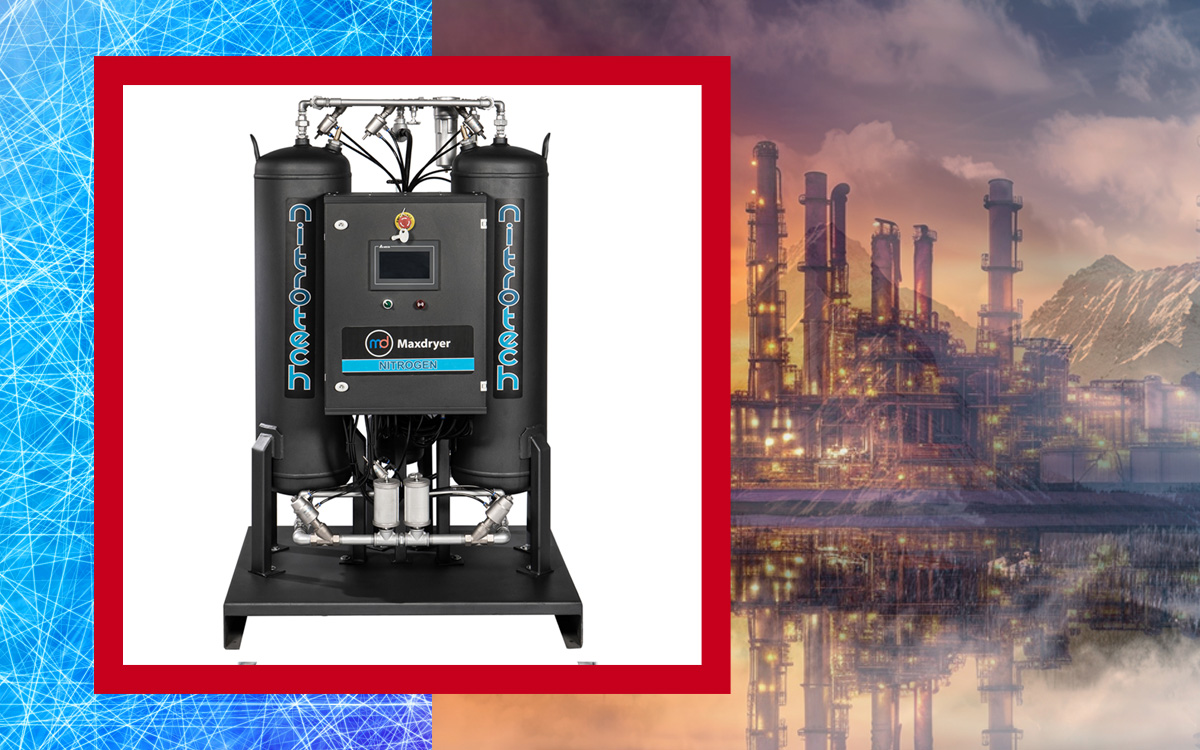

Nitrogen generators have become indispensable in industrial processes. By producing high purity nitrogen, it increases productivity, improves product quality and reduces costs in many sectors. With innovative solutions offered by specialized companies such as Maxdryer, nitrogen generators will continue to become even more widespread in today's industry.

Key words: nitrogen generator, nitrogen gas, nitrogen generators, nitrogen generator, nitrogen gas, industrial gas, laser cutting nitrogen gas, laser cutting nitrogen generator, food industry, electronic industry, chemical industry, metal processing, power sector, high purity nitrogen, continuous nitrogen supply, cost saving, environmentally friendly, safe use.

Contact us immediately for your nitrogen generator needs.