Why Use a Nitrogen Generator in Laser Cutting?

Laser cutting is a common method used in today's manufacturing industry to precisely cut metals. In this process, many factors influence the quality and efficiency of the cut. One of these factors is the auxiliary gas used. One of the most commonly used auxiliary gases in laser cutting is nitrogen, and in this article, we will examine in detail why nitrogen generators are so important.

Laser Cutting Process and the Role of Nitrogen

In laser cutting, a high-energy laser beam heats the surface of the material, melting and vaporizing it. The auxiliary gas used in the process controls the atmosphere in the cutting zone, affecting the efficiency and quality of the process.

- Oxidation Prevention: Nitrogen is an inert gas, meaning it does not react easily with other substances. This prevents the material from coming into contact with oxygen during laser cutting, preventing oxidation. Oxidation can cause unwanted color changes on the surface of the material, corrosion and loss of performance.

- Improving Cutting Quality: Nitrogen increases the pressure in the cutting zone, allowing molten metal to be removed more quickly and cleanly. This results in flatter, smoother and burr-free cutting edges.

- High Cutting Speed: The use of nitrogen increases the speed of laser cutting. This significantly increases production efficiency.

- Material Protection: Nitrogen prevents thermal damage to the cut material. This is especially important when processing sensitive materials.

- Environmentally Friendly: Nitrogen generators are more environmentally friendly than bottled gas. As they provide a continuous gas supply, cylinder replacement and transportation are eliminated.

Advantages of Nitrogen Generator

- Continuous and Pure Nitrogen Supply: Nitrogen generators ensure continuous and high purity nitrogen production. This increases efficiency in production processes.

- Cost Savings: It is more economical than using bottled gas.

- Environmentally Friendly: Eliminates the environmental impacts associated with bottled gas transportation and storage.

- Safe Use: The nitrogen generator is designed and manufactured in accordance with safety standards.

Importance and Details of Nitrogen Use in Laser Cutting

- Different Types of Lasers: The use of nitrogen may differ for different types of lasers such as CO2 lasers, fiber lasers, etc.

- Azot Saflığı: The purity of the nitrogen used in laser cutting applications directly affects the cutting quality.

- Nitrogen Pressure: Nitrogen pressure affects parameters such as depth and speed of cut.

- Nitrogen Flow Rate: Nitrogen flow rate is important to prevent oxidation on the cutting surface.

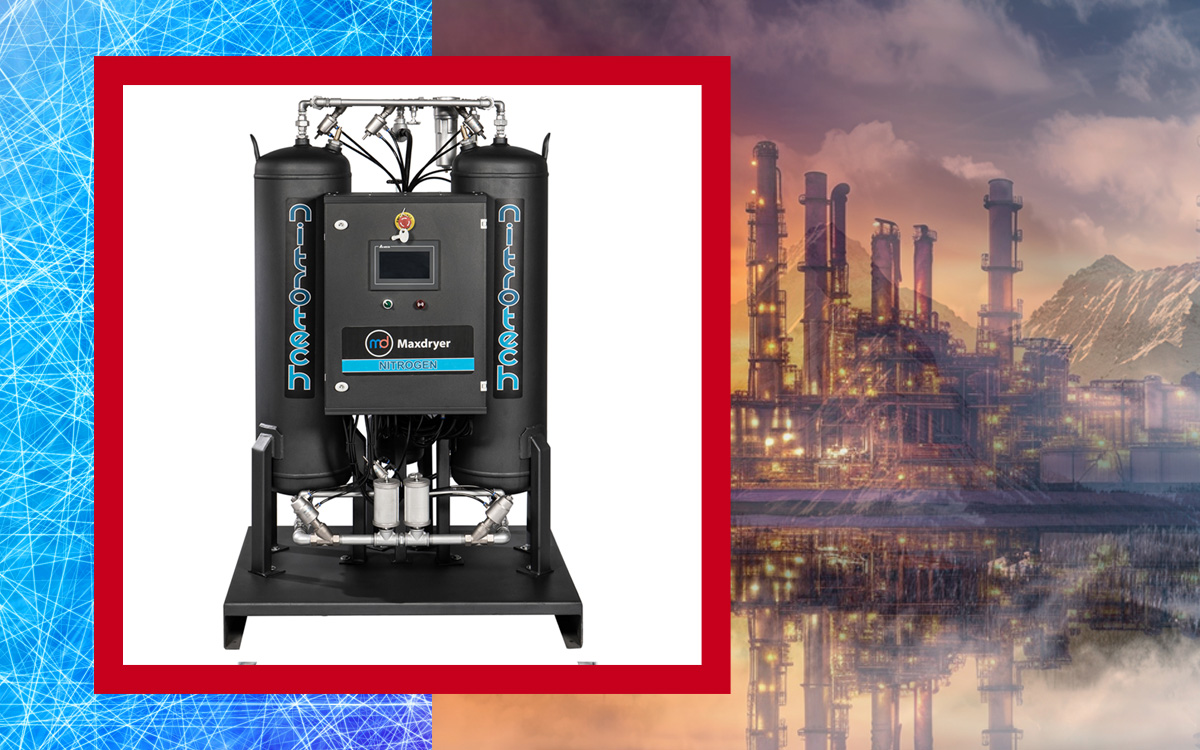

Use Max Dryer Nitrogen Generator for Perfect Cutting!

The use of nitrogen generators in laser cutting is essential to improve cutting quality, increase production efficiency and reduce costs. The inert nature of nitrogen prevents oxidation, extending the life of materials and providing more aesthetic results. For this reason, nitrogen generators have become indispensable equipment, especially in applications requiring high precision.

Nitrogen generators in laser cutting are the preferred solution to improve cutting quality, increase production efficiency, reduce costs and create an environmentally friendly production process.

Keywords: nitrogen generator, nitrogen gas, nitrogen generators, nitrogen generator, nitrogen gas, industrial gas, laser cutting nitrogen gas, laser cutting nitrogen generator, food industry, electronic industry, chemical industry, metal processing, energy sector, high purity nitrogen, continuous nitrogen supply, cost saving, PSA nitrogen generator, Max Dryer, nitrogen generation, industrial gas, carbon molecular sieve, inert atmosphere, food industry, pharmaceutical industry, metal processing, electronics industry, Map Food Gas, Nitrogen generator, Nitrogen generators, eco-friendly, safe use, laser cutting, nitrogen generator, auxiliary gas, oxidation, cutting quality, production efficiency, cost, environmentally friendly

Contact us immediately for your nitrogen generator needs.

Nitrogen Generator