Modified Atmosphere Packaging (MAP) and Fruit and Vegetable Preservation with Natural Compounds An Innovative Approach with Max Dryer

Delivering fresh fruits and vegetables to consumers in the best way possible is one of the most important goals of the food sector. However, losses that occur during storage and transportation processes create serious problems for both producers and consumers. The main causes of these losses include physiological deterioration, microorganism activity and physico-chemical changes. Along with traditional methods to overcome these problems, the trend towards natural and sustainable solutions has increased in recent years. In this study, the use of modified atmosphere packaging (MAP) technology in combination with natural antimicrobial compounds and its effects on fruit and vegetable quality will be investigated.

What is Modified Atmosphere Packaging (MAP)?

Modified atmosphere packaging (MAP) is a technology that extends the shelf life and preserves the quality of the product by changing the gas composition in food packaging. In this method, the oxygen level in the package is reduced, while carbon dioxide and nitrogen generator and the proportion of gases such as nitrogen is increased. In this way, respiration rates are reduced, microorganism activity is inhibited and product maturation is slowed down.

Role of Natural Antimicrobial Compounds

Natural antimicrobial compounds are substances produced by plants, animals, and microorganisms that inhibit or slow the growth of other microorganisms. These compounds can be used to extend the shelf life of foods, inhibit pathogenic microorganisms, and ensure food safety. Natural antimicrobial compounds such as plant extracts, essential oils, and bacteriocins can have synergistic effects when used with MAP and may be more effective in preserving the product.

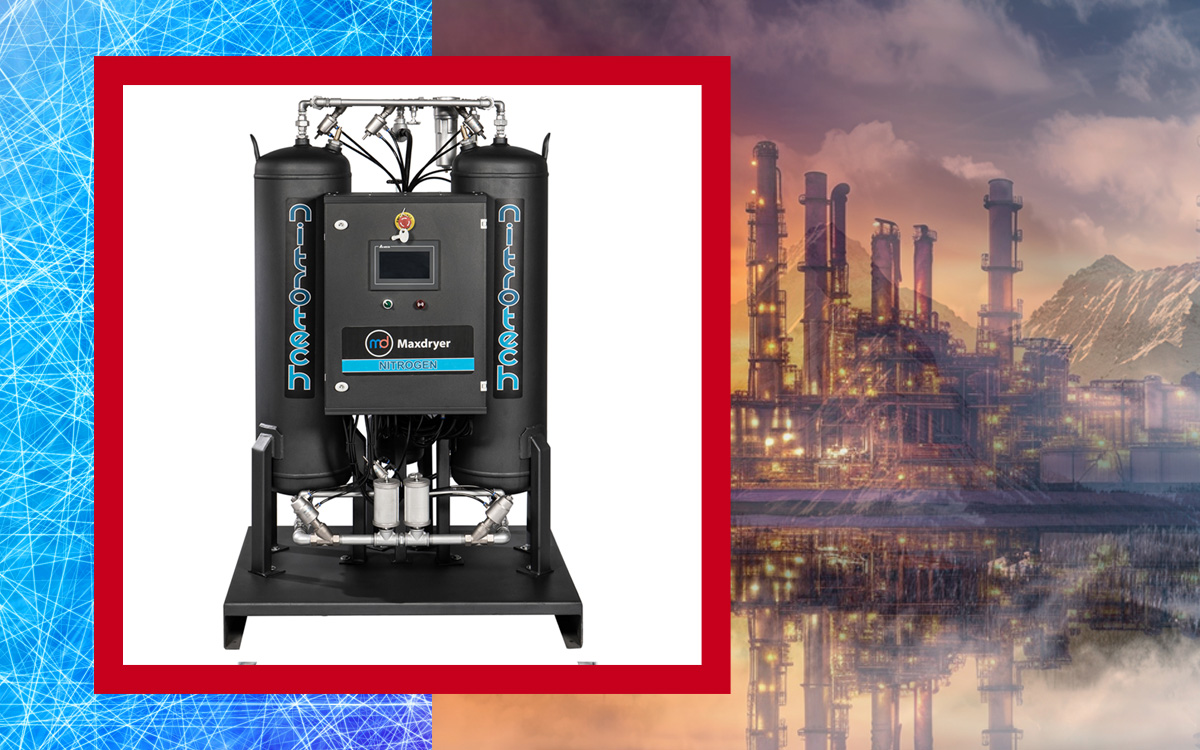

Max Dryer MAP Systems

Developed by companies such as Max Dryer, MAP systems offer flexible and easy-to-use solutions that can adapt to packages of different sizes and specifications. These systems allow precise control of the gas concentration in the package. They can also be customized according to the specific needs of different products.

Benefits of Combined Use of MAP and Natural Compounds

- Extending Shelf Life: The combined use of MAP and natural antimicrobial compounds significantly extends the shelf life of the product, reducing food losses.

- Quality Protection: This method increases consumer satisfaction by preserving the freshness, color, texture and nutritional value of the product for longer.

- Microbial Growth Control: Natural antimicrobial compounds inhibit the growth of pathogenic microorganisms, ensuring food safety.

- Reducing Physiological Disturbances: MAP delays physiological deterioration by reducing respiratory rate and decreasing ethylene production.

- Reducing the Use of Synthetic Preservatives: The use of natural compounds reduces the need for synthetic chemical preservatives, resulting in healthier products.

- Market Expansion: It enables long-distance transportation, enabling products to reach wider markets.

The combination of modified atmosphere packaging (MAP) and natural antimicrobial compounds is an effective strategy for preserving fresh fruits and vegetables. MAP systems developed by companies such as Max Dryer are making significant contributions to the widespread use of this technology and its increased use in the food sector. In this way, a more sustainable and healthy food system can be created for both producers and consumers.

Cost Items of MAP Systems

The total cost of MAP systems varies depending on several factors. These factors include;

- Size and Capacity of the System: The production capacity and product range of the enterprise is one of the most important factors determining the size and therefore the cost of the system.

- Technologically Advanced: Level of automation of the system, nitrogen generator other factors affecting cost, such as gas control features and data collection capabilities.

- Equipment Cost: The cost of equipment such as gas generators, vacuum pumps, sensors and control units significantly affects the total cost.

- Installation and Integration Cost: The cost of civil, electrical and automation works required to integrate the system into the existing production line should also be considered.

Return on MAP Systems

The benefits of MAP systems can justify the investment. These benefits include;

- Extending Shelf Life: Extending the shelf life of products reduces food losses and increases profitability.

- Increased Product Quality: MAP increases consumer satisfaction by preserving the freshness, color and texture of products.

- Market Expansion: By enabling long-distance transportation, it enables reaching new markets.

- Brand Image: By creating a natural and healthy product image, it increases the competitiveness of the brand.

Cost-Benefit Analysis

The cost-benefit analysis of MAP systems is a detailed study that should be carried out according to the specific situation of the enterprise. In this analysis, the following factors should be considered:

- Return on Investment: It should be calculated how long the investment will pay for itself.

- Gıda Kayıplarındaki Azalma: The financial value of reduced food losses through the MAP system should be calculated.

- Additional Revenue from Increased Product Quality: Calculate the additional revenue that would be generated if higher quality products were sold at higher prices.

- The Impact of Market Expansion: Additional income from reaching new markets should be calculated.

Reduce Food Losses with MAP Food Systems!

MAP systems offer significant benefits for both producers and consumers in the food sector by maintaining the freshness and quality of products. However, the implementation of these systems requires significant initial investment. Therefore, it is important to conduct a detailed cost-benefit analysis before investing and make a decision based on the specific situation of the business.

Note: This article is about the Max Dryer Map Food Gas nitrogen generator provides a general information about. For more detailed information, you can contact Max Dryer officials.

Key words: nitrogen generator, nitrogen gas, nitrogen generators, nitrogen generator, nitrogen gas, industrial gas, laser cutting nitrogen gas, laser cutting nitrogen generator, food industry, electronic industry, chemical industry, metal processing, energy sector, high purity nitrogen, continuous nitrogen supply, cost saving, PSA nitrogen generator, Max Dryer, nitrogen generation, industrial gas, carbon molecular sieve, inert atmosphere, food industry, pharmaceutical industry, metal processing, electronics industry, Map Food Gas, nitrogen generator, nitrogen generators, environmentally friendly, safe use, modified atmosphere packaging, MAP, cost analysis, food, freshness, shelf life, investment, payback period

Contact us immediately for your nitrogen generator needs.

Nitrogen Generator