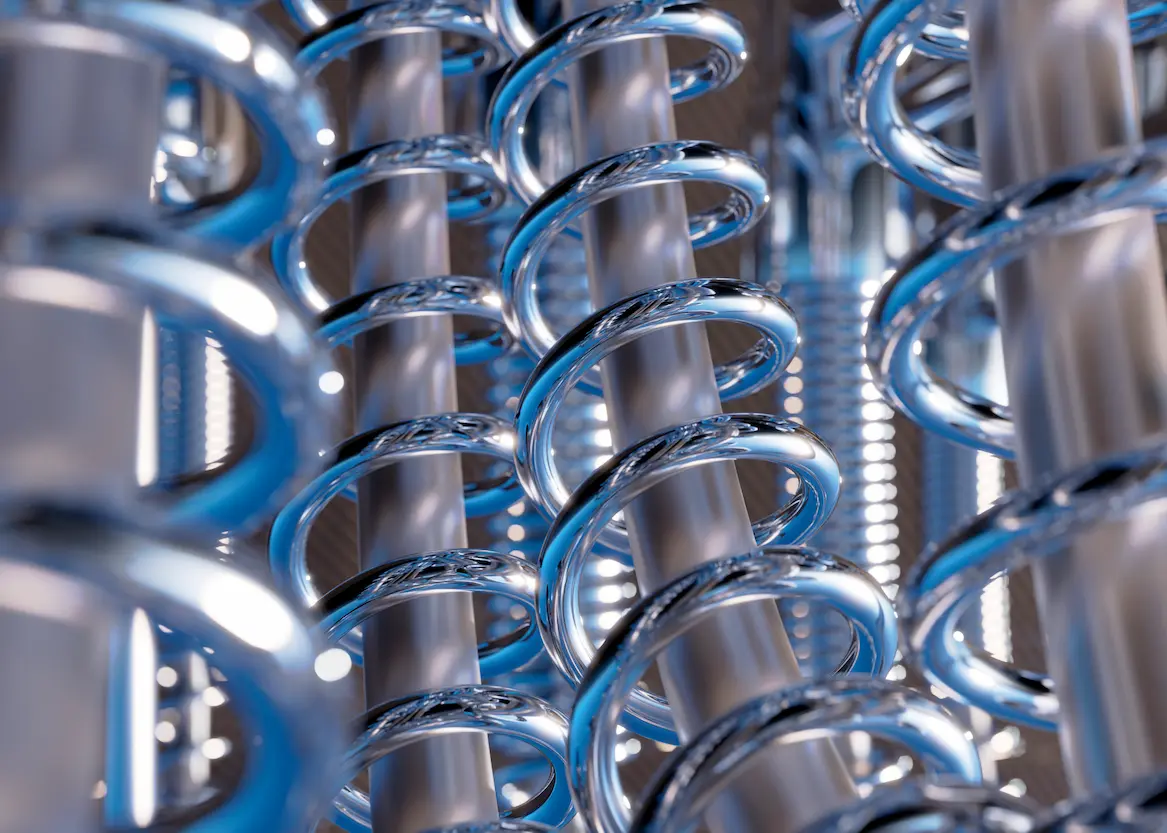

The Indispensable Solution for Production Quality and Efficiency in the Shock Absorber Industry

Shock absorber manufacturing is a specialized production process that requires high pressure and precision. From nitrogen gas filling to sealing tests, from welding to surface coating, the use of quality compressed air and gas at every stage is vital for the performance and reliability of the final product. Maksimum Makina guarantees the reliability of your production processes with solutions developed specifically for the needs of the shock absorber industry.

The shock absorber industry produces parts that are critical to vehicle safety and ride comfort. Manufacturing these components requires high purity gas and dry air quality in processes such as precision welding, leak testing and oil filling. The slightest contamination or moisture in production directly jeopardizes the performance and life of the product.

Maksimum Makina offers system solutions that meet the specific needs of shock absorber manufacturers and increase production quality and efficiency.

Critical Maximum Machine Products in Shock Absorber Production

1. Nitrogen Generators: Source Quality and Oil Life Guarantee

In the production of shock absorbers, Nitrogen gas (N₂) is used for two main purposes: protection in welding processes and protection of the oil inside the product.

- Areas of Use:

- Protective Welding Atmosphere: To prevent oxidation during welding of shock absorber bodies and parts, obtaining stronger and cleaner weld seams.

- Oil and Gas Filling: To maintain the purity of the oil or gas (usually Nitrogen) filled into the shock absorber and prevent air/moisture from entering the system. High purity Nitrogen gas extends shock absorber oil life and prevents loss of performance.

- Maximum Machine Solution: PSA Type Nitrogen Generators, produces the high purity N₂ gas (typically 99.999% purity) required for shock absorber filling and welding processes continuously, reliably and economically on-site.

2. Compressed Air Dryers and Filtration Systems

Sealing is the most critical feature of the shock absorber. Test equipment and pneumatic systems must be protected from moist air.

- Adsorption Type Dryers:

- Areas of Use: Shock absorber tightness test benches, precision measuring instruments and valves.

- Benefits: By minimizing air humidity (-40°C or -70°C dew point) ensures consistency of test results. Moisture can cause erroneous readings in tightness tests or initiate corrosion in pneumatic systems.

- High Efficiency Filters and Activated Carbon Tower:

- Areas of Use: Compressed air supply lines.

- Benefits: Particle, rust and oil vapor Cleaned air prevents valve failures and extends the life of precision assembly equipment.

3. Chiller Cooling Systems: Process Temperature Control

Temperature control is important during machining, welding and testing of shock absorber components.

- Areas of Use:

- Welding Machine Cooling: To prevent overheating of welding machines and transformers used in shock absorber body and piston rod welding processes.

- Mold and Press Cooling: Precise and rapid cooling of molds used in the production of shock absorber seals and other plastic/rubber parts.

- Benefit: Ensures the continuous stable operation of production equipment, maintains part dimensional tolerances and reduces maintenance-related downtime.