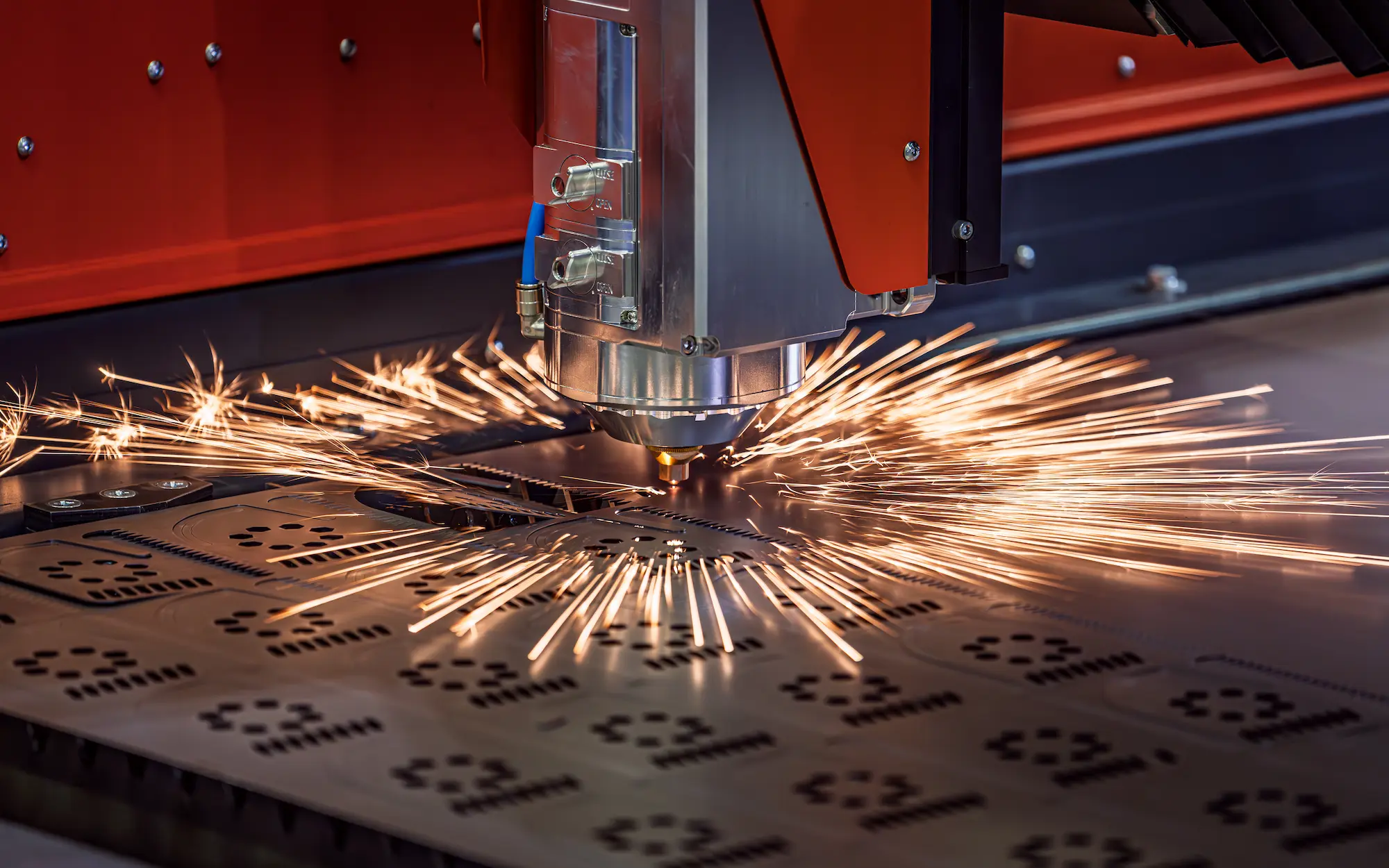

LASER CUTTING INDUSTRY

Laser Cutting Technologies and Solutions

As Maksimum Makine, we offer innovative solutions to maximize productivity and quality in the laser cutting industry. The key to success in laser cutting systems is the quality of the equipment used and the determination of the right parameters. Factors such as the thickness and type of metal being cut, cutting time and machine technology are meticulously evaluated in our projects.

Parameters such as thickness, material type and cutting speed directly affect the quality of the final product. However, optimizing these parameters is not limited to the laser machine. The purity of the auxiliary gas and the quality of the compressed air used during cutting are the most critical factors determining the efficiency, cost and cut quality of the operation.

For High Thickness and Flawless Cutting: Ultra Pure Nitrogen Generators

Laser cutting of materials such as stainless steel and aluminum uses high purity nitrogen gas to prevent oxidation of the cutting surface and achieve a perfect, bright cutting edge. The traditional solution is to supply liquid nitrogen, but this method carries high operating costs, storage challenges and the risk of supply interruption.

Maksimum Makina's Ultrapure Nitrogen Generator Systemswill solve these problems once and for all. 99.9999% purity (O2 level less than 1 ppm) and high-pressure nitrogen gas in your own facility in an uninterrupted and economical way.

Excellent Cutting Quality with High Purity Nitrogen Generator

Laser cutting nitrogen gasis a critical element that directly affects the quality of the cut. The use of high purity (1 ppm O2) and abundant nitrogen gas is mandatory, especially when cutting high thickness metal sheets. Instead of traditional liquid nitrogen supply methods, Maksimum Makine has developed Ultrapure Nitrogen Generators you can produce nitrogen gas with 99.9999% purity in your own facility. This system both reduces costs and ensures uninterrupted and high quality production.

These generator systems not only meet your consumption, but also create the necessary gas stock by filling the manifold with 230 bar pressure. This gives you flexibility and safety in your operations.

The system includes the following components:

- Compressor

- Water and Particulate Filter

- Compressed Air Dryer

- Activated Carbon Tower

- Air Tank

- Nitrogen Generator

- Azot Booster Compressor

- Nitrogen Manifold

This integrated structure, tailored to your needs, provides a stable and reliable nitrogen source for your laser cutting operations.

Advantages of the Nitrogen Generator System:

- High Business Economics:Continuous nitrogen production using only electrical energy at a much lower cost than liquid nitrogen.

- Uninterrupted Production:By eliminating supply chain dependency, it reduces the risk of gas interruptions to zero.

- Excellent Cutting Quality:With 1 ppm O2 level, it provides burr-free, bright and oxide-free cutting even on high-thickness sheet metal.

- Complete Integrated System:The system includes high-pressure (230 bar) manifold filling, meeting your needs for laser cutting as well as spare cylinder filling.

Maximum Air Oil-Free Dry Air Systems

Cutting Up to 4 Times Faster Than Oxygen

When cutting materials like carbon steel, galvanized sheet metal, and mild steel, high-pressure, dry air provides much faster and more efficient cutting than oxygen. However, the "dry air" here isn't the same as that from a standard compressor. It's crucial that the air reaching the laser cutting head is completely free of oil, water, and particles.

Maksimum Makina's Maximum Air Oil-Free Dry Air Systems produce "cutting air" that meets the ISO 8573-1 Class 1.2.1 standard (oil content: Class 1, water content: Class 2, particulate: Class 1), at 18 barg and a dew point of +3°C. Thanks to this oil-free and moisture-free air, metal cutting can be done 2-4 times faster than with oxygen cutting.

These systems, which can operate between 13 and 25 bar, provide precise and burr-free cuts in materials such as carbon steel, aluminum, galvanized sheet metal, and DKP. This way, you can both reduce production time and improve end-product quality.

Maximum Air Oil-Free Dry AirSystem Advantages:

- High Speed and Efficiency:It offers 2 to 4 times faster cutting compared to oxygen cutting.

- Superior Cutting Quality:Clean air, free from oil and moisture, prevents burr formation on the cutting edge and provides precise and clean cutting.

- Equipment Protection:Protects critical components of the laser cutting machine, such as the nozzle and lens, from the negative effects of oil and moisture, extending their life and reducing maintenance costs.

- Working in the Range of 13-25 BAR:Provides the ideal pressure for different material thicknesses and cutting modes.

At Maksimum Makina, we're here to provide the most efficient solutions for your laser cutting needs. If you'd like to learn more about our products to optimize your production processes and gain a competitive advantage, please contact us.